A centerless machine with a constant center of threading

Only one machine setup needed even for long workpieces

![]()

![]()

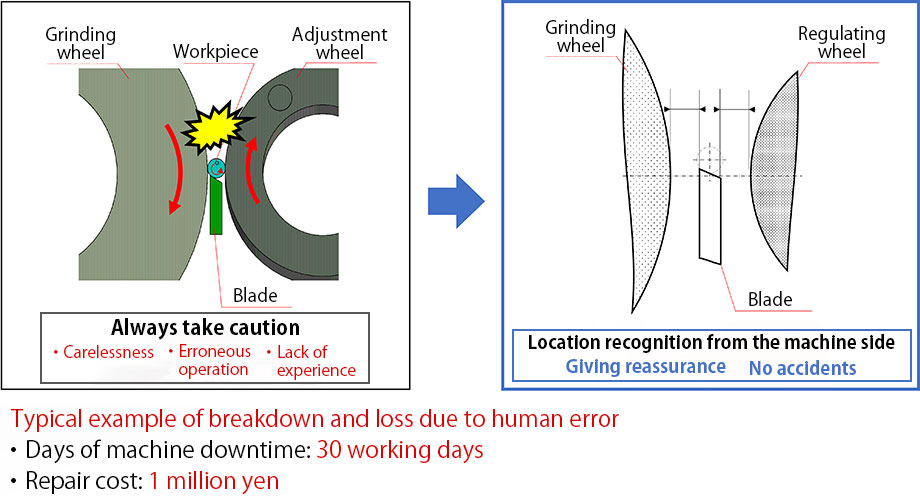

This Grinding Machine is equipped with a function that recognizes position information as its standard, so even individuals unfamiliar with the machine can use it with peace of mind.

Bar feeder

Stocker

|

|

|

|

|

| Dimensions | φ20×L2000 | φ20×L2000 | φ9×L4000 | φ25×L3000 |

| Material | Titanium alloy | — | S45C | S45C |

| Roundness | 7.0 | 7.0 | 7.0 | 10.0 |

| Cylindricity(μm) | 10.0 | 10.0 | 10.0 | 10.0 |

| Surface roughness(μm) | Ra0.4 | Ra0.4 | Ra0.4 | Rz5.0 |

※The values are based on requirements.

*Please view the table by scrolling horizontally

The issue

With regards to the setup and adjustment unique to grinding long workpieces, it is difficult to pass down adjustment and engineering techniques. Also, because it is not possible to quantify it is not possible reduce time and stabilize production.

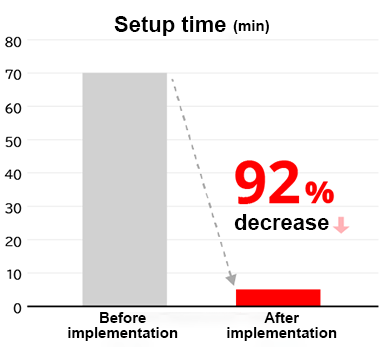

After implementation

By implementing our Centerless Grinder specialized for long workpieces, it became easier to reproduce setups. Together with the linking of the supply and discharger device, it led to a successful reduction of setup time by 92%.

| Format | TO-6040T-FC-TF | |

|---|---|---|

| Grinding performance | Processing diameter | 20~60㎜ |

| Processing length | Max1000㎜ | |

| Grinding wheel | Dimensions | φ610×405×φ304.8 |

| Minimum diameter | φ430 | |

| Maximum peripheral speed | 2700m/min | |

| Motor capacity | 37kW(NC spindle motor) | |

| Adjustment wheel | Dimensions | φ330×405×φ203.2 |

| Minimum diameter | φ270 | |

| Revolution per minute | 1~500rpm | |

| Motor capacity | 5.5kW(NC spindle motor) | |

| Machine dimensions | W3130㎜×D1500㎜×H2150㎜ | |

| Machine weight | 8500kg | |

*Please view the table by scrolling horizontally

Standard specifications

Selectable specifications

Specialized specifications

A wide range of accessories to meet a wide range of needs