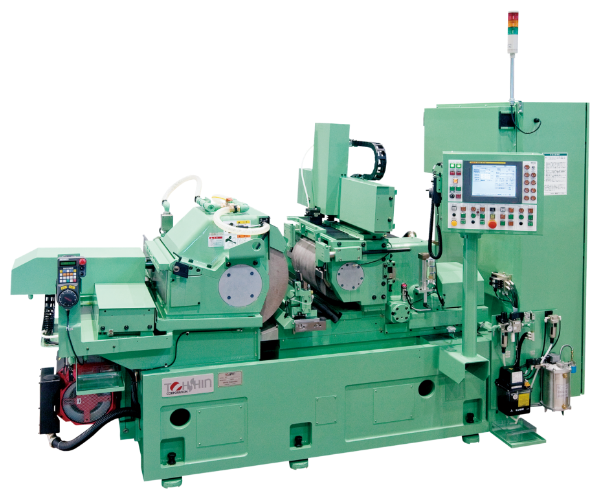

A high cost performance machine with enhanced options and multi functionality

Also with improved workability and a lower price compared to conventional machines

![]()

![]()

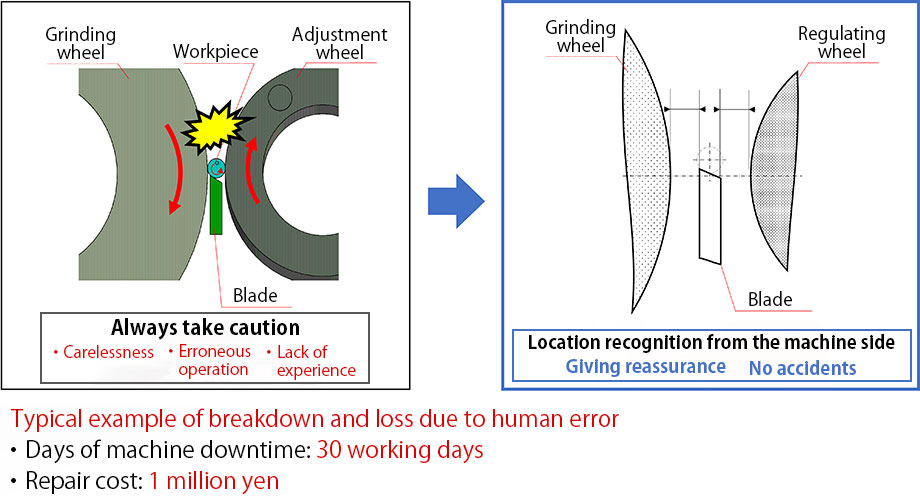

This Grinding Machine is equipped with a function that recognizes position information as its standard, so even individuals unfamiliar with the machine can use it with peace of mind.

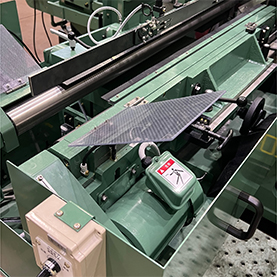

Ring feeder

Conveyer

Parts feeder

Gantry loader

|

|

|

|

|

| Dimensions | φ30×L726 | φ116×L8 | φ22×L20 | φ120×L31 |

| Material | — | SUJ2 | SUJ2 | SUJ2 |

| Roundness | 5.0 | 10.0 | 2.0 | 3.0 |

| Cylindricity(μm) | 10.0 | 3.0 | 2.0 | 3.0 |

| Surface roughness(μm) | Rz1.6 | Ra1.6 | Ry4.0 | Rz4.0 |

※The values are based on requirements.

*Please view the table by scrolling horizontally

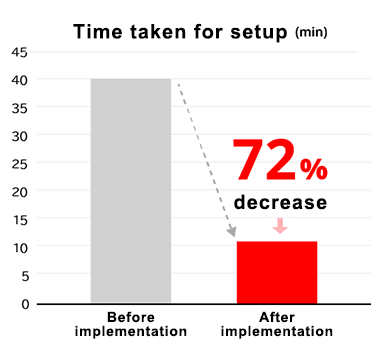

The issue

With a high-mix small-lot production system, it is difficult to pass down adjustment and engineering techniques. Because it is not possible to quantify them, it is not possible to reduce time and stabilize production.

After implementation

By implementing our Centerless Grinder with automatic setup support function, it became easier to reproduce the setup and cut down setup time by 72%. With this, even a beginner can use the same setup as a highly skilled worker.

| TO-6045ⅡT | TO-6040ⅡT | TO-6030ⅡT | ||

|---|---|---|---|---|

| Grinding performance | Processing diameter (standard) | φ3~120㎜(φ40~160㎜) | ||

| Processing diameter (large) | φ50~170㎜(φ90~210㎜) | |||

| Processing diameter (extra-large) | φ100~220㎜(φ140~260㎜) | |||

| Processing length (infeed) | 450㎜ | 400㎜ | 300㎜ | |

| Grinding wheel | Dimensions | φ610×455×φ304.8 (7A type) |

φ610×405×φ304.8 | φ610×305×φ304.8 |

| Minimum diameter | φ430㎜ | |||

| Maximum peripheral speed | 2700m/min | |||

| Motor capacity | 37kW (30kW、22kW) |

30kW (37kW、22kW) |

22kW (30kW、15kW) |

|

| Adjustment wheel | Dimensions | φ330×455×φ203.2 (7A type) |

φ330×405×φ203.2 | φ330×305×φ203.2 |

| Minimum diameter | φ270㎜ | |||

| Driving system | Belt driving | |||

| Revolution per minute | 1~500rpm(NC spindle motor) | |||

| Motor capacity | 5.5kW | 5.5kW | 3.7kW | |

| Machine dimensions | W2880×D1550×H2000 | W2880×D1550×H2000 | W2880×D1400×H2000 | |

| Machine weight | 6500kg | 6300kg | 6100kg | |

| Electrical capacity | 45kVA | 40kVA | 35kVA | |

| Amount of air used | 160Nℓ/min | |||

*Please view the table by scrolling horizontally

Accessory equipment and features included in the price of the machine

Attachments not included in the price of the machine

Optional functions (specialized attachments)

A variety of optional features available to meet all needs