A high performance machine that handles from infeed multi-cavity grinding to throughfeed super abrasive grinding

![]()

![]()

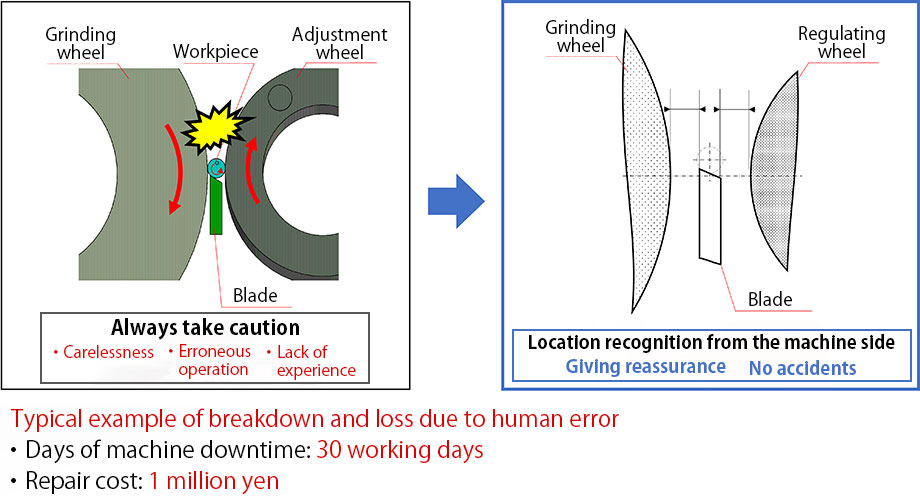

This Grinding Machine is equipped with a function that recognizes position information as its standard, so even individuals unfamiliar with the machine can use it with peace of mind.

Conveyer

Parts feeder

Gantry loader

Stocker

|

|

|

|

|

| Dimensions | φ23×L80 | φ22×L27 | φ1×φ2×L33 | φ37×L33 |

| Material | SCM440H | — | Tap material | SCM415 |

| Roundness | 3.0 | 1.5 | 10.0 | 4.0 |

| Cylindricity(μm) | 2.0 | 2.5 | 10.0 | 4.0 |

| Surface roughness(μm) | Rz0.3 | Ra0.25 | Ry3.2 | Ra0.6 |

※The values are based on requirements.

*Please view the table by scrolling horizontally

The issue

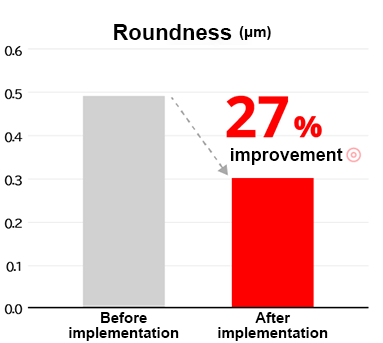

The customer wants to further improve roundness with infeed grinding

After implementation

By implementing our Centerless Grinder that specializes in roundness as well as by reviewing the grinding process, the roundness was improved by 27%. Because of the improved roundness, the outer diameter dimensions were stabilized and productivity was improved.

| SigmaⅡ 4020T | SigmaⅡ 4520S | SigmaⅡ 4515S | Sigma 4015T | ||

|---|---|---|---|---|---|

| Grinding performance | Processing diameter | φ2~50mm | φ3~60mm | φ1~50mm | |

| Processing length | 200mm | 200mm | 145mm | 145mm | |

| Scale feedback | ○ | ○ | ○ | ● | |

| Bearing structure | Double-sided | Cantilevered | Double-sided | ||

| Grinding wheel | Dimensions | φ405×205×φ228.6 | φ455×205×φ228.6(7A type) | φ455×150×φ228.6 | φ405×150×φ228.6 |

| Minimum diameter | φ310 | φ360 | φ310 | ||

| Maximum peripheral speed | 3000m/min | 3000m/min | 3000m/min | ||

| Motor capacity | 11kw | 7.5kw(11kw) | 7.5kw(11kw) | 7.5kw(11kw) | |

| Adjustment wheel | Dimensions | φ305×205×φ177.8 | φ305×205×φ177.8 | φ305×150×φ177.8 | φ305×150×φ177.8 |

| Minimum diameter | φ255mm | φ255mm | |||

| Driving system | Belt reducer | Belt reducer | |||

| Revolution per minute | 1~750rpm | 1~750rpm | |||

| Motor capacity | 3.5kw (AC servo motor) | 3.5kw (AC servo motor) | |||

| Machine dimensions | 2450×1500×1950(※) | 2450×1500×1950(※) | |||

| Machine weight | 4500kg | 4500kg | |||

●Standard ○Factory options

(※)Machine size including control panel

*Please view the table by scrolling horizontally

Standard specifications (standard attachment functions)

Optional (specialized attachments)