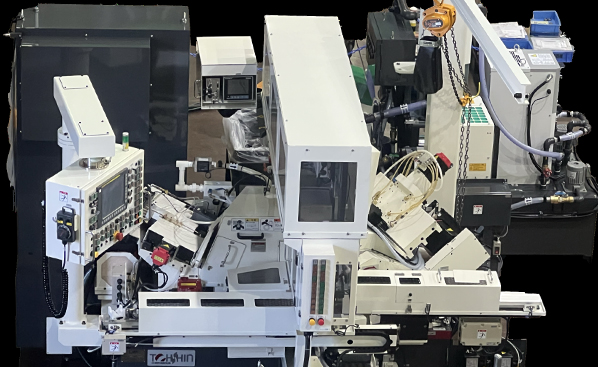

What we offer is a “total grinding system.”

We strive to design and propose the best grinding system even for the most unique of products

so that our clients can reap the rewards once they implement it.

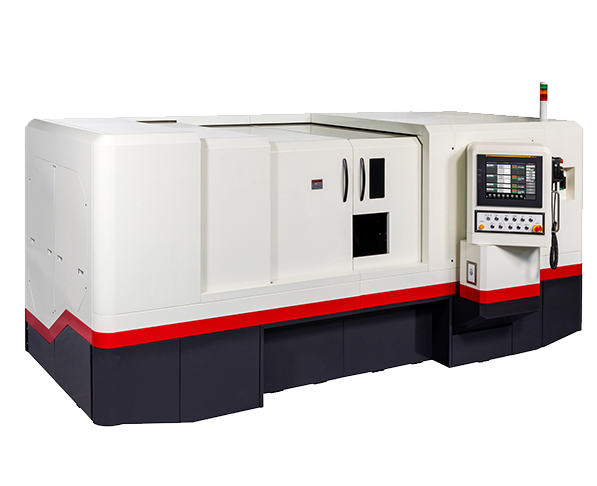

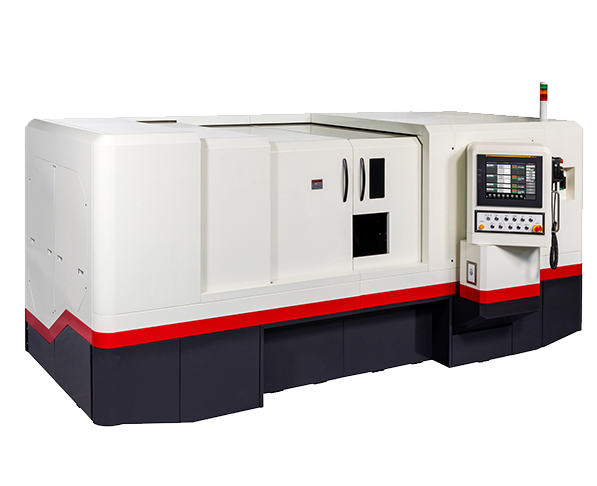

“To make high precision products, we must have high precision machine tools,” was the commitment that led to the birth of Centerless Grinders.

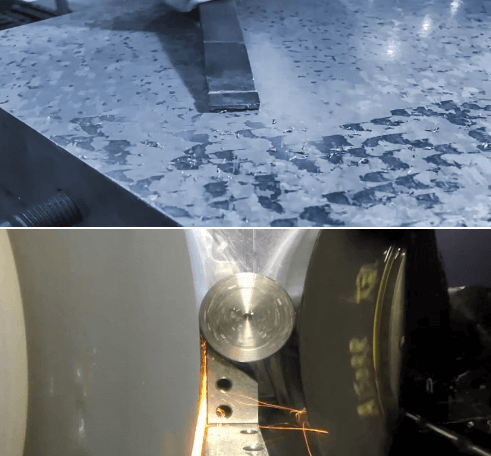

The technological prowess of Centerless Grinders has been proven by Tohshin rollers and the technical improvements of the rollers, cultivated in the day by day manufacturing, have been reflected in Tohshin Technical’s Centerless Grinders.

Tohshin Technical’s strength is that it has a field where it can see manufacturing from the perspective of production site.

With an advanced grinding system design and Tohshin Group's grinding know-how based on "craftsmanship" that processes and assembles all major parts, we will cooperate in solving customer's problems.

As “technology partners,” Tohshin Technical works together with clients to solve any issues they may have and create a grinding method that works for them.

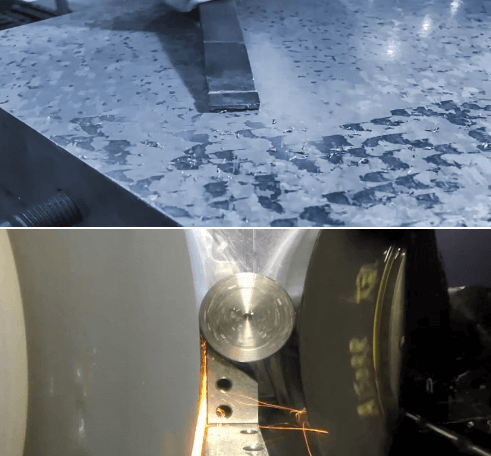

Here we introduce types of Centerless Grinders according to the shapes of workpiece.